Introduction

In the ever-evolving world of construction and engineering, precision, efficiency, and collaboration are no longer optional—they’re essential. As projects become more complex, the approach to designing mechanical, electrical, and plumbing (MEP) systems must evolve as well. This is where BIM MEP (Building Information Modeling for MEP systems) comes into play, offering a revolutionary alternative to traditional MEP design.

This comparative study explores the key differences between BIM MEP and traditional MEP design, examining how BIM is reshaping the industry and why forward-thinking firms like HTC Design have fully embraced this digital transformation.

What is Traditional MEP Design?

Traditional MEP design involves 2D drafting methods, typically using AutoCAD or manual drawings. Engineers and consultants work in silos, creating separate design plans for HVAC, plumbing, and electrical systems. Coordination among disciplines is often handled manually during site meetings or via red-line markups.

Limitations of Traditional MEP Design

Lack of coordination: Leads to clashes between systems.

Time-consuming revisions: Every change must be manually updated in all drawings.

Limited visualization: 2D designs don’t offer real-world perspectives.

Increased site rework: Misaligned systems can lead to costly errors.

Delayed detection of conflicts: Most issues arise only during construction.

What is BIM MEP Design?

BIM MEP uses intelligent 3D models to plan, design, and coordinate MEP systems in a shared digital environment. With software like Revit, Navisworks, and BIM 360, all stakeholders—including architects, engineers, and contractors—can collaborate on the same model.

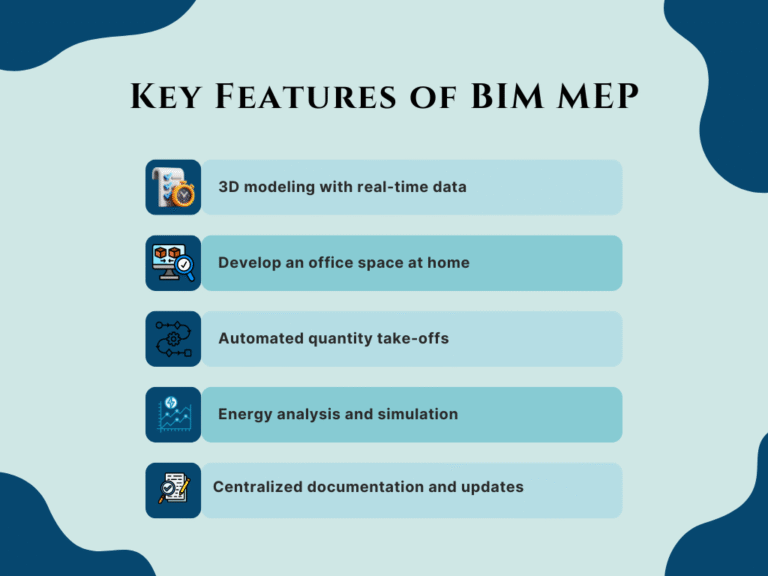

Key Features of BIM MEP

3D modeling with real-time data

Clash detection before construction

Automated quantity take-offs

Energy analysis and simulation

Centralized documentation and updates

Why BIM MEP is Gaining Global Popularity

1. Enhanced Collaboration

BIM MEP encourages a shared model environment where all disciplines contribute. Architects, structural engineers, and MEP professionals can work simultaneously, reducing miscommunication and ensuring coordinated output.

2. Clash Detection & Coordination

With tools like Navisworks Manage, HTC Design identifies interferences—like a duct clashing with a beam—before construction begins. This significantly cuts down on rework and delays.

3. Time and Cost Efficiency

Automated processes, quantity take-offs, and real-time updates reduce time spent on documentation. Fewer clashes and streamlined coordination mean lower construction costs and minimized project delays.

4. Accurate Material Quantification

BIM MEP models generate precise Bill of Quantities (BOQs), which are essential for procurement planning. Unlike traditional design, there’s no guesswork involved.

5. Lifecycle Data for Facility Management

BIM supports post-construction maintenance through the integration of data such as manufacturer specs, warranty information, and service schedules. Traditional MEP design does not extend this support beyond the handover.

Real-World Example: HTC Design’s Approach

At HTC Design, all MEP projects are executed through BIM platforms. Here’s how the firm leverages BIM MEP to outperform traditional design methods:

Project Kickoff: All teams are brought onto a common data environment using Revit and BIM 360.

Design Development: Intelligent MEP families are modeled and coordinated in 3D.

Clash Detection: Weekly Navisworks reviews help identify and resolve issues early.

Client Review: Stakeholders receive walk-throughs of the 3D model rather than deciphering 2D plans.

Facility Data Delivery: The final model includes embedded data for asset management post-handover.

This method saves time, improves clarity, and ensures smooth execution on-site.

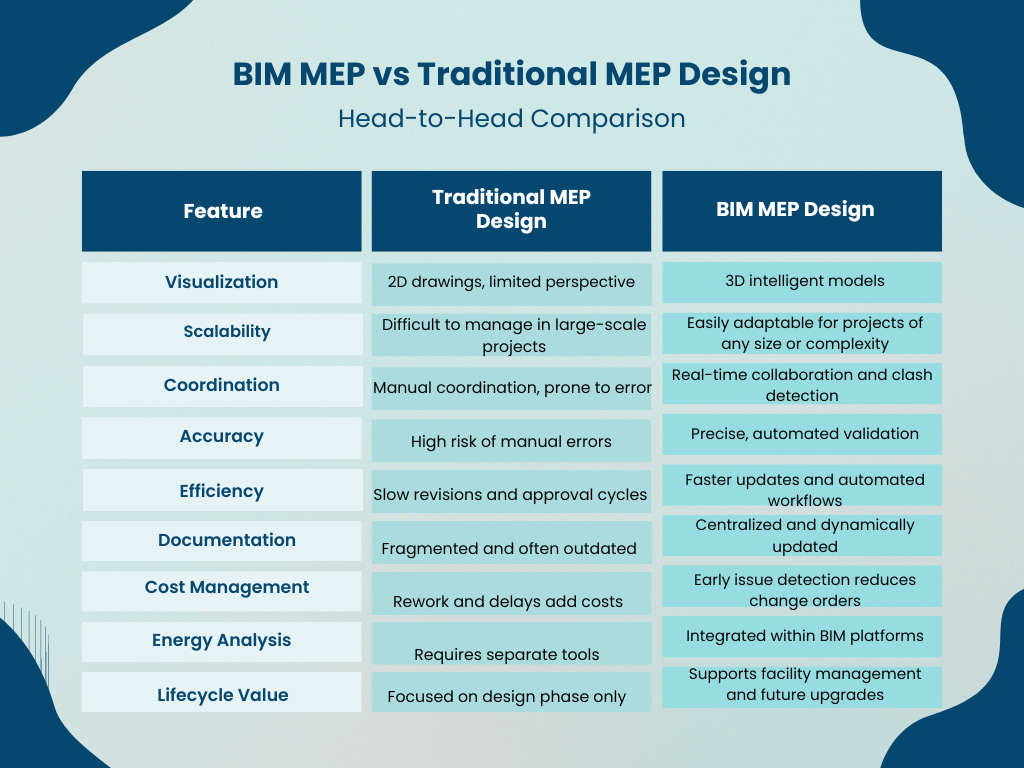

Head-to-Head Comparison: BIM MEP vs Traditional MEP Design

Challenges of Adopting BIM MEP (and Overcoming Them)

While the benefits are clear, BIM MEP also presents some challenges:

1. Initial Investment

BIM tools and training require upfront cost. However, the ROI in terms of reduced errors and faster project delivery far outweighs the expense.

2. Skill Requirements

Traditional teams may lack the expertise for BIM. HTC Design overcomes this through ongoing team training, workshops, and hiring BIM-certified professionals.

3. Data Management

Handling large model files and data sets can be overwhelming. Cloud platforms like BIM 360 and structured data management practices help keep everything organized.

Final Verdict: BIM MEP is the Future of Design

The gap between BIM MEP and traditional MEP design continues to widen. While traditional methods may still have a place in smaller projects, the industry at large is moving toward smart, collaborative design platforms that reduce waste, increase precision, and improve outcomes.

For firms seeking long-term success, like HTC Design, BIM MEP isn’t just an upgrade—it’s the foundation for delivering intelligent, future-ready building systems.

Conclusion

The transition from traditional MEP design to BIM MEP is not just a technological leap—it’s a strategic shift. BIM MEP offers unmatched coordination, accuracy, and lifecycle benefits that traditional design simply cannot match. As construction demands continue to rise, firms that adopt BIM-based workflows are better positioned to lead in quality, efficiency, and innovation.

Choose HTC Design for reliable, accurate, and future-proof BIM MEP solutions—because your project deserves more than outdated methods.